South West Flooring Market Visit

Linda McDonald • April 28, 2021

Every year Dallas hosts the Southwest Flooring Market, where people in the industry can see what’s available and what’s new in the world of hardwood flooring. Recently, Bryan Jones, owner of Temple Johnson Floor Company, caught the 2021 show and shared what he came away with.

“I have to say, I was a little disappointed because the show ended up being smaller than usual, due to Covid, but there were many striking displays to take in. It looks like the wider European French Oak and brushed white oak, that were popular last year, are still trending. But now they are graduating to 8-inch, 9-inch, and even 10-inch planks. And in longer lengths, as well—up to 8 feet.”

The new hot item the reps were all talking up was “smoked oak.” Having been in the business for thirty years now, Jones recognized the technique, and asked them if they meant “fumed” oak. “That’s what they were calling it quite a few years back,” he said, “and it’s basically the same approach.”

The process works by putting oak in a closed container and subjecting it to ammonia, which creates heat. “That pulls the tannins in the wood up through the surface, which brings out tones within the actual grains, rather than just the grain. The longer it’s left in the container, more numerous dark tones emerge. There will be mineral streaks around it, which makes the wood darker.”

While it produces a beautiful effect, Jones warned it has some drawbacks. “You have basically impregnated that dark shade throughout the wood,” he explained, “so if you decide later you want to sand and refinish that wood, be aware that the overall color will stay the same. Once it’s been fumed, the effect can’t be changed.”

There was also lots of chatter about new pre-engineered waterproof floors, which are guaranteed by their companies, even in flooding conditions. But, again, experience in the industry has made Temple Johnson wary about jumping in at the moment. Bryan believes the jury’s still out over whether the waterproof claims will hold up over time. “There’s always movement in a wood floor, depending on the dryness or wetness within the wood, so you can still get cracks.” And cracks mean water gets in. He plans to keep an eye on it.

The industry is seeing promising innovations in oil-based wood finishes, which have always had a beautiful hand-rubbed look. The problem was the amount of maintenance they took. It had to be done by hand, and was labor intensive, so most people eventually turned to floor professionals to keep them up.

Now, however, they have developed spray-on materials that do the job just as well—including mops where you can just pop the trigger as you clean, making it much simpler to maintain. “Because they were so tricky, we’ve largely stayed away from them. But if this new rejuvenation technique proves to be workable, it would be a future offering with Temple Johnson.”

Texas Post Oak was a product from Valencia that definitely caught Bryan’s attention. The name comes from their wood source—post oak trees left on deserted farms or where the trees are no longer needed. It’s called “post oak” because farmers made their fence posts out of it. A naturally aged wood, it has a polyurethane water-based finish. With its distinctive look and name, it could have wide appeal here in Oklahoma.

Everyone at the market agreed that, even though it is on its way back, supply and demand still have a powerful hold on the wood flooring industry. “And with Covid, the prices at each step can increase before you can get the product to the United States,” Jones said.

Some small overruns the service professional can absorb, but, in extreme circumstances, some may have to be renegotiated. Most clientele are understanding, if it comes to that. There’s not much anybody can do right now, with a struggling work force and hundreds of container ships sitting idle in ports all over the world.

Well-known flooring companies, such as Mastercraft and Adleta, have warned their clients they will need longer lead times, and that the price could change even as late as the day you pick the materials up. Plus, if you let your delivery sit for too many days, they’ll ship it out to somebody else. Both companies announced price increases across the board.

In Oklahoma City, plywood has gone up $20 a sheet, and flooring up 30 cents a square foot. And right now, white oak is difficult to find anywhere. “That doesn’t mean you can’t get a new floor,” he added with a smile, “but the client may want to look at other choices to minimize delays.”

Consider switching from white oak to red oak is his first suggestion. That not only saves the customer some money, but red oak is easier to find now. “I don’t know why the white oak is more popular than the red, really,” he added. “Basically, white oak has a yellowish cast and red oak has a reddish cast. Both are equally beautiful.”

Supply and demand problems have touched all industries, not just wood flooring companies. But Temple Johnson always stands ready to guide their clients to plan earlier, allow for longer lead times, and choose products that will hasten the way to a timely and gorgeous hardwood floor.

Engineered wood flooring is quickly becoming a top pick for homeowners who want the elegance of hardwood with the added benefit of durability. Made with multiple layers of wood, including a hardwood veneer on top and stable plywood underneath, this type of flooring is built to last through changing seasons and daily wear and tear. If you’re looking for a flooring option that blends beauty with practical performance, engineered wood is a game-changer. It brings the timeless look of traditional hardwood without many of its downsides. The Advantages of Engineered Hardwood Flooring: There are many reasons why Oklahoma City homeowners are choosing this versatile flooring option: • Climate Compatibility: Oklahoma’s seasonal changes bring humidity and dryness. Engineered wood handles moisture fluctuations better than solid hardwood, reducing the risk of warping or gapping. • Design Flexibility: It comes in a wide range of wood species, finishes, plank sizes, and textures—perfect for both modern and rustic interiors. • Ease of Installation: With options for glue-down, nail-down, or floating installation, it works well in a variety of spaces and over different subfloors. • Sustainability: Engineered wood uses less hardwood overall and often incorporates renewable resources in its layered construction. • Low Maintenance: Simple sweeping and occasional damp mopping are enough to keep it looking great. Best areas to Use Engineered Wood Flooring: One of the greatest benefits of engineered wood flooring is its adaptability. Engineered planks can go just about anywhere. Popular installation areas include: • Living rooms • Bedrooms • Dining rooms • Finished basements • Entryways • Kitchens (with proper sealing) Its stability makes it especially suitable for rooms that experience temperature or humidity shifts throughout the year. Engineered Wood Flooring in Oklahoma Homes: When remodeling or building, Temple Johnson Floor Company is a reliable choice that offers long-term value. It provides the aesthetic warmth of hardwood and the structural benefits of modern engineering. Many families love how it brings coziness into a space while holding up to kids, pets, and heavy foot traffic. Because of its layered construction, it also works well over radiant heating systems and concrete slabs, where solid hardwood may not be an option. Maintenance Tips for Long-Lasting Floors: To keep your engineered floors in top condition: • Place mats at entrances to catch dirt • Use furniture pads to avoid scratches • Clean spills promptly with a damp (not wet) cloth • Avoid steam cleaning or harsh chemical cleaners Following these steps helps preserve the finish and extends the life of your flooring. Ready to Explore Engineered Wood Flooring?: Engineered wood flooring offers the perfect balance of style, comfort, and performance. Whether you’re renovating a single room or planning a whole-home update, this flooring delivers long-term beauty and value. To get expert guidance and high-quality options, call Temple Johnson Flooring at (405) 842-0112 or contact us online https://www.templejohnsonfloorco.com/flooring-quote for your personalized flooring quote.

Spring is here! We understand that natural urge to wash away the previous year and start fresh by cleaning your home from the ceiling all the way down to that gorgeous hardwood floor, so we've come prepared to help! Here is the general cleaning process that we recommend to all of our hardwood flooring customers (that don’t have a wax finish on top, that is*), which should help alleviate any concern about what is and isn’t safe to clean your wood flooring with. Fortunately, the routine is quite simple! We recommend cleaning your floors bi-weekly, and as needed to accommodate for unforeseen daily messes and spills, with a dust mop or microfiber pad, and a cleaner such as Bona brand Wood Floor Cleaner. Be mindful of getting just the bottle that reads “Wood Floor Cleaner” or “Professional Wood Floor Cleaner”, and NEVER purchase any product that states that it “Polishes, Shines, and/or Restores in 1 Coat”. BONA’s wood floor cleaner is non-toxic, and unlike other wood floor cleaners it doesn’t leave behind streaks or residue if applied properly. Beyond regular weekly cleaning, feel free to use your wood floor cleaner to clean up after a spill or on tougher stains and residue build-up. STEP #1: Sweep and/or dust mop with a soft-bristled broom or pad. (The specific product pictured below is just an example, anything similar that doesn't have any abrasive elements will work perfectly fine!)

Worried about your family's furriest member scratching up your wood flooring? Don't fret! Beyond the fact that all of us at Temple Johnson simply love dogs & cats, we also extend that passion to the wood flooring that they and the rest of your family live on. Although there isn’t any one specific way to curb the scratching that your furry friends can and will inevitably inflict upon your wood flooring, we’ve provided some tips and small strategies that can actually help keep your floor looking nice!

This is a wonderful write-up on 12 different common household situations that can very well lead to the degradation and destruction of your home's hardwood flooring, and the article was written originally by Mark Melendres of Home Decor Bliss, and the link to the article itself can be found at the bottom of this page!

A beautifully stained hardwood floor grabs our senses in the same way an extraordinary painting does. The artist’s subject, color choices and perspective pull us in for a closer examination. When studying handsome hardwood floor designs, our eyes are entertained the same way. We are fascinated by the way the light reflects different shades and even a sense of movement in the wood grain. The appeal of the room is enriched not only by the chosen hue of the stain but also the particular species of the wood flooring. All the customer’s personal preferences act together to form the impression they want the floor to make. Just as a painter juggles the elements of a canvas—the subject, size, tone, and effect—stain color choices start with the aesthetics of the owner/creator. Plenty of us “know what we like” and are ready to jump in on our own. And why not? Examples of wood floors are plentiful for us to check out. Websites like Pinterest, or hardwood flooring company’s sites offer inspiring examples that may be just what you are looking for. However, most people would rather have an experienced studio artist paint their portrait. Why not use a hardwood floor specialist as “a guide by your side” through the entire process? Temple Johnson Flooring, a century-old, family-owned business that has treated clients like family for decades, is the perfect place to find this support. Owners Bryan Jones and Matt Sparks are hardwood floor specialists who represent decades of experience. They have the talent to listen to what you want and make it happen.

The real world demands a lot of people’s time today. We’re asked to fill out endless questionnaires, for instance, before every doctor’s appointment. Ask yourself: how long did you have to sit on hold to speak to a real person at a corporation? It sometimes seems unreal, the red tape people are subjected to today. What may be surprising, and also real, is that a huge project such as buying engineered hardwood flooring today is simpler and more cost effective than ever. It’s amazing how many expenses have been removed from the process. In most cases it costs less than traditional hardwood flooring, but is also easier to install, so complex scheduling over several weeks has become a headache of the past. One common misconception about engineered flooring is that when people hear the term, they assume it is a man-made veneer, not real wood. At Temple Johnson Floor, after clients see the engineered showroom samples, owners Bryan Jones and Matt Sparks are always asked the same question. “Is that real wood?” And their answer is always, “It absolutely is.” Engineers and flooring specialists have come up with an ingenious new way to craft real wood floors. It is here and growing larger every day. For reference, traditional wood floors are solid hardwood planks installed over plywood decking, then sanded and stained on the job site. Traditional floors require more procedures that all have to be coordinated with the client and other workers on the premises (painters, electricians, for example). Engineered floors are constructed using several layers of real wood, which is uniquely configured. On top sits the real hardwood veneer, firmly supported by ¼” layers of crisscrossed different species of wood. It is available finished or unfinished.

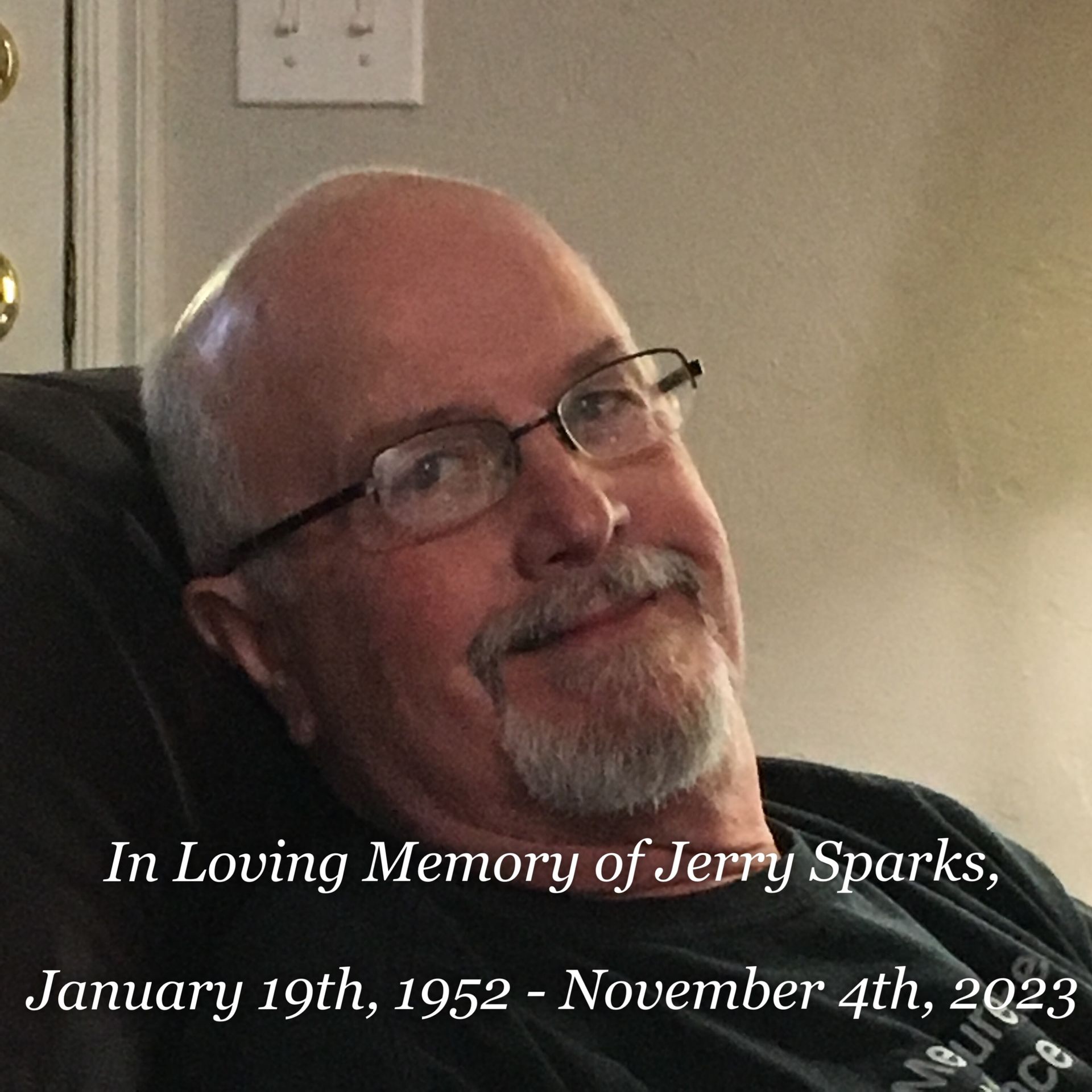

It is with a heavy heart that we announce the passing of someone that was integral to Temple Johnson Floor Company, Jerry Sparks. As a family owned-and-operated company, this was a heavy blow. We would like to take this opportunity to reflect on the innumerable amount of people that he touched the lives of through his work here at Temple Johnson, and the flooring industry in general, customer or otherwise. While his servant’s heart led Jerry’s life, he also led by example with his hands, accomplishing a profound amount as a small business owner and as an inspiration to others through his hard work. Upon purchasing the company in 1978 from Pauline Johnson & Jimmy Martin, Jerry owned and operated Temple Johnson Flooring Company from 1979 to 1992. He then sold the business to his brother-in-law and promptly started his own home-building business, Chance Matthew Homes, named after his sons.

Hardwood flooring is enjoying a popular resurgence in Herringbone, a familiar and ancient pattern. The design gets its name from the delicate skeletal structure of herring. The fish’s bones slant in a V-shape pattern as they spread away from the spine. This is a fantastic example of the general structure we're talking about here:

Are you looking to upgrade the aesthetics of your home while adding a touch of elegance and warmth? Look no further than Temple Johnson Flooring here in Oklahoma City! We are thrilled to present our exceptional collection of hardwood flooring options to help you elevate the beauty of your living spaces to new heights. With our extensive range of high-quality hardwood materials and professional installation services, we are committed to helping you achieve the home of your dreams. Let's dive into the captivating world of hardwood flooring and explore why it is the ideal choice for homeowners seeking sophistication and durability. There's a reason why hardwood flooring has remained a timeless classic since the advent of human history. Its natural beauty and warm tones bring a sense of vibrancy and luxury to any room. We accomplish this with the help of a wide variety of wood species, grains, and finishes offered here at Temple Johnson, which in turn affords you the ability to choose a style that perfectly complements your interior design preferences and goals. From the rich, traditional hues of oak to the exotic allure of Brazilian cherry, all of our hardwood flooring options will create an ambiance that reflects your unique personality and tastes, and ultimately enhance the overall aesthetic of your home. Wood flooring has brawn to back up all that beauty, as well! Investing in hardwood flooring means investing in longevity. With proper care and maintenance, hardwood floors can withstand the test of time, maintaining their beauty and structural integrity for decades on end. Our hand-selected wood flooring brands that we've partnered with are crafted using the finest materials and expert craftsmanship, ensuring durability and longevity. Whether you have a busy household with kids and pets or you simply want flooring that can withstand daily wear and tear, our hardwood floors are designed to stand up to the challenges of essentially any lifestyle. With all of that in mind, it becomes quite clear that one of the greatest advantages of hardwood flooring is its versatility. It effortlessly complements a wide range of interior styles, from traditional to modern and everything in between. The rich undertones and different tones brought out by simply changing the wood floor stain can help it remain adaptable to your interior design changes over a lifetime. Because of this, here at Temple Johnson we offer an extensive selection of finishes, stains, and plank sizes to cater to your individuality and creative preferences for your home. Whether you desire a rustic farmhouse look, a sleek and modern contemporary vibe, or a timeless traditional feel, our hardwood flooring options can be customized to match your vision. Keeping your hardwood floors looking pristine is surprisingly simple! Regular sweeping and occasional gentle mopping with Bona Hardwood Floor Cleaner is all it really takes to maintain their natural luster. A recent EPA study also found that hardwood floors greatly reduce the accumulation of toxins. Unlike carpet that trap dust, allergens, and pet dander, hardwood floors are hypoallergenic and contribute to improved indoor air quality, and in a state like ours with allergens abound, this increased air quality is truly a life-changer for many of us. With hardwood flooring from Temple Johnson Flooring, you can enjoy a cleaner and healthier living environment, perfect for individuals with allergies or respiratory sensitivities.

French Parquet wood flooring was originally designed to replace historic estates’ stone and marble floors. Those rigid surfaces eventually wreaked havoc on the mansions’ enormous wood frameworks. Parquet wooden floors, on the other hand, built using 3’ x 3’ square units, proved far more forgiving than the historic rock-hard surfacing. Not only did French Florentine Parquet prove architecturally functional, but also became universally famous for its eye-catching designs. Recently, Temple Johnson Floor was approached about a custom wood floor design. It called for scaling down a French parquet’s standard 3’ x 3’ squares to only 2’ x 2’. Clients could never order such a one-of-a-kind design through today’s big box, wholesale flooring stores, who depend on volume sales. It would be difficult to order them from anywhere, really, even though the clients had hoped to begin as soon as possible.